Polycarbonate sheets can withstand massive force and are virtually unbreakable. As a result, they are used in the construction of bulletproof windows and police shields, it's UV treated and suitable for outdoor environment, and they have a high quality that makes them the best choice for pergola roofing, skylights, patio, awnings, etc.

Polycarbonate also can be used as Translucent facades, as light glazing panels used on the exterior of buildings, protecting the structure from weather damage, dampness.

Advantages of polycarbonate sheets

-

Lightweight and Easy Installation: Polycarbonate sheets are lightweight, only half weight of glass, making them easy to transport and install. This characteristic also reduces labor costs during installation.

-

Weather Resistance: Excelite Polycarbonate panels are all UV treated, are resistant to heat, sunlight, snow, and rain, ensuring longevity without fading or discoloration, making them ideal for greenhouses pergola and outdoor structures.

-

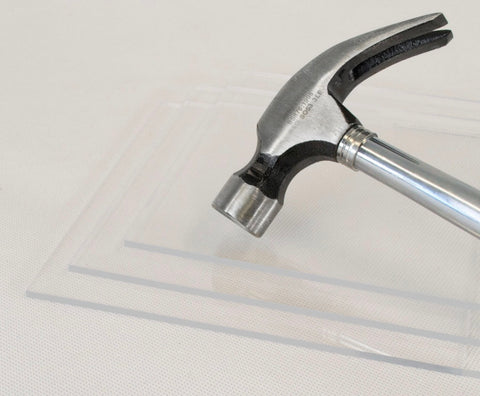

Impact Strength: Polycarbonate sheets offer 250 times impact resistance compared to glass, 30 times stronger than Acrylic sheet, making them suitable for areas where durability is essential.

-

Design Versatility: Available in clear and tinted grey shades, polycarbonate sheets can be colored or translucent, offering flexibility in design and application.

-

UV Protection: Polycarbonate sheeting block harmful UV rays while allowing sunlight to pass through, making them ideal for greenhouse construction and outdoor use without yellowing or fading over time.

-

Energy Efficiency: With good thermal insulation properties, polycarbonate sheets help reduce heating and cooling costs by minimizing heat transfer through the material. Daylights offered by polycarbonate are natural light transmitters that direct sunlight into various parts of a building to reduce energy costs.

-

Wide Range of Applications: Polycarbonate sheets are used in various industries, from construction and architecture to household products and industrial equipment, due to their versatility and durability.

-

Easy Machining: Polycarbonate sheets can be easily machined, drilled, bent, and shaped using standard tools, allowing for custom designs and applications.

-

Sustainability: Polycarbonate sheets have a long lifespan and are recyclable, making them an environmentally friendly choice for sustainable building projects.

- High Level Fire rating: Polycarbonate is used as a Class B1 fireproof material. Non-flammable, and self-extinguishing away from the fire

- Wide work temperature range: Polycarbonate maintains its properties over a wide range of temperatures, from -20 to 140°C, which is much wider range than Acrylic sheet.

- Bendable, Flexible

- Easy to cut, no crack

- Esthetics: Polycarbonate roof can be customized because the material is flexible. A polycarbonate roof is appealing to the eye, making it an asset to a building’s esthetics and a welcome addition to the community, whether it’s a residential section or a commercial area.

Disadvantages:

-

Cost: Polycarbonate sheets can be more expensive than other perspex sheet or glass, impacting overall project costs.

-

Scratch Susceptibility: They are prone to scratches, dents, and marring, requiring careful handling and maintenance to preserve their appearance.

-

Chemical Sensitivity: Polycarbonate sheets are sensitive to certain chemicals and solvents, requiring caution during cleaning and handling.

-

Limited Chemical Resistance: Polycarbonate is susceptible to attack by many organic solvents, which may limit its use in certain applications.

-

Aromatic Sensitivity: Clear polycarbonate can yellow over time due to exposure to UV light, affecting its optical clarity and appearance.

-

Stress Cracking: Clear polycarbonate is prone to stress cracking under certain conditions, requiring careful consideration in design and usage.

- Not suitable for food contact: Some types of PA may not be suitable for direct food contact due to concerns about potential leaching of bisphenol A (BPA).

Despite these drawbacks, polycarbonate sheets remain a popular choice for their unique combination of strength, versatility, and durability in various applications across different industries.

2 comments

Clement

Where can I get the sheets in Johannesburg

Where can I get the sheets in Johannesburg

Clement

Where can I get the sheets

Where can I get the sheets