ExcelitePlas

Acrylic sheets for aquarium and pool windows

Thickness

Size

Acrylic sheets for aquarium and pool windows

15mm / 1220*2440mm

Dandenong South Warehouse

6 Stephen Road

Dandenong South VIC 3175

Australia

Choose options

Thickness

Size

Thickness

Size

Acrylic panel is an outstanding material for constructing aquariums and swimming pool windows, particularly larger ones. It is easy to work with, withstands impacts much better than glass (it won't shatter like glass), and is much lighter.

Although glass is more scratch-resistant than acrylic block, repairing a scratch in acrylic sheets is much easier than fixing one in a glass aquarium.

Acrylic is also less reflective than glass, enhancing the viewing experience, particularly in well-lit rooms

Product Features

- PVHO-1 (Pressure Vessel Human Occupancy) 2019 certification by DNV-G

- 30-year UV guarantee.

- Panel size availability ranging up to currently 9300mm x 3100mm.

- Specially developed bonding technology enabling further lengths.

- Thickness range (over 750mm - 2 feet 5.5 inches)

- Expert thermo-forming, on site bonding & fabrication options available.

- Leading optically clear quality.

- Excellent surface hardness (scratch resistance).

Product thickness and sizes:

All customisable

For thickness more than 30mm, please contact us for a quote.

Q: What is pool window?

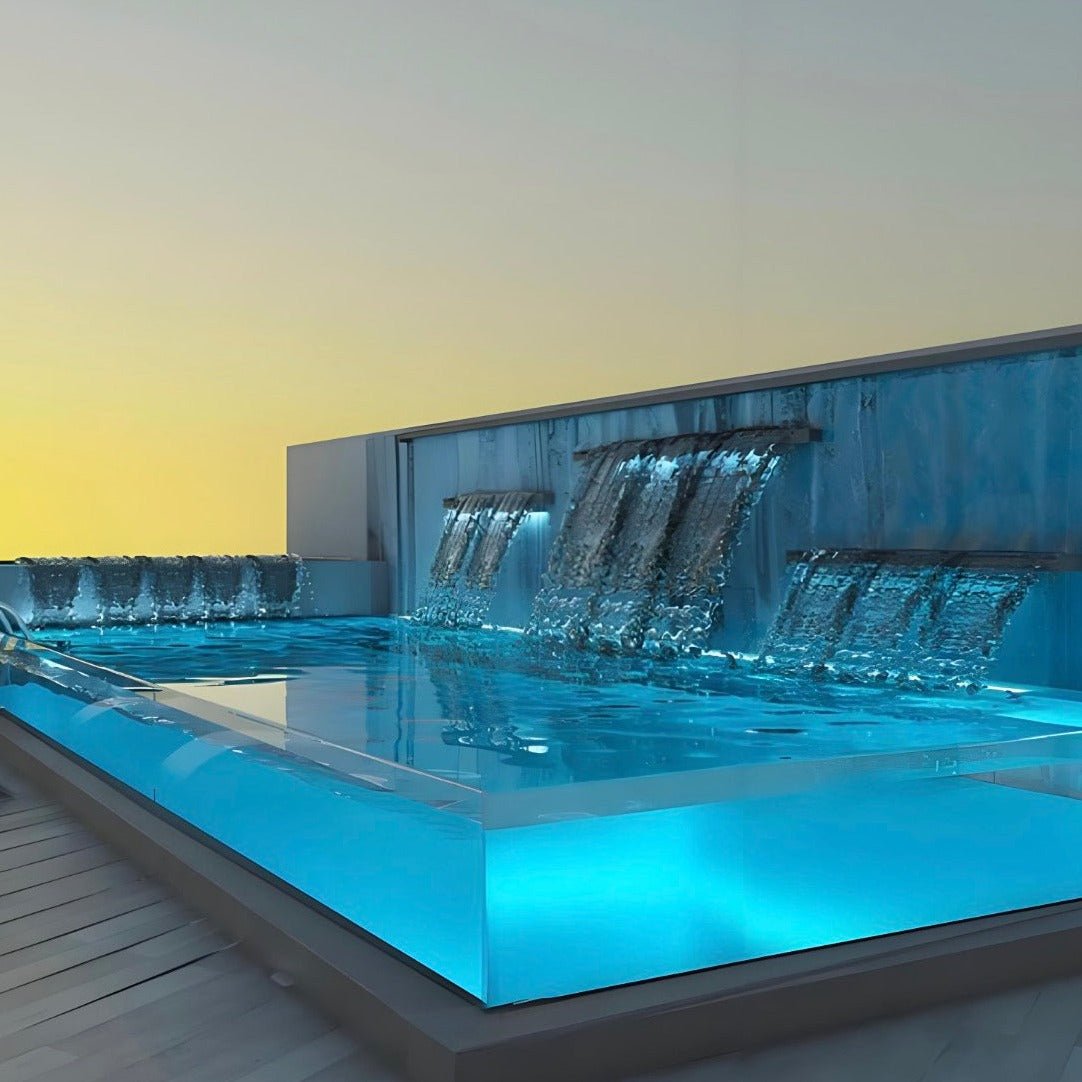

A: A pool window is a transparent section of the pool wall, typically made from thick acrylic sheet or polycarbonate panel, that allows people to see into the pool from outside. Pool windows can also be called underwater windows or viewing panels. They are commonly used in both residential and commercial pools, including public aquariums, hotel aquarium pools, and private luxury pools, container pools.

Reasons for Having a Pool Window:

-

Aesthetic Appeal: Pool windows add a unique and visually striking element to your pool design, creating a modern and luxurious look.

-

Enhanced Viewing Experience: Pool with a window allow for a unique perspective, enabling observers to watch swimmers underwater, which can be particularly entertaining in pools with diverse aquatic life or intricate designs.

-

Natural Light: Swimming Pool windows can help introduce natural light into indoor pools or adjacent spaces, enhancing the overall ambiance.

-

Safety: In some cases, pool windows can improve safety by allowing for better monitoring of swimmers from outside the pool, making it easier to spot someone in distress.

-

Photography and Filming: They provide excellent opportunities for underwater photography and videography without the need for specialized equipment or getting wet.

-

Educational Purposes: In public aquariums and educational facilities, pool windows allow for better observation and study of aquatic life and behaviors.

-

Architectural Integration: Pool windows can seamlessly integrate the pool area with surrounding spaces, such as a living room or outdoor entertainment area, creating a more cohesive and open design.

-

Luxury and Exclusivity: They are often associated with high-end and exclusive properties, enhancing the perceived value and appeal of the pool and the property overall.

What is the glass around pool call?

Q: Why glass is not allowed around pool?

Comparison Between Acrylic and Polycarbonate

Acrylic and polycarbonate are both versatile plastics with various applications. While they share some similarities, they also have differences that are important to consider for your specific use.

Here is a comparison between acrylic and polycarbonate:

Clarity: Acrylic has more exceptional clarity, boasting a transparency rate of up to 93%, compared to polycarbonate, which generally offers around 89% light transmission.

Strength

Polycarbonate is more robust, providing 200 times the strength of glass, while acrylic is about 10 times stronger than glass. Polycarbonate is more suitable for applications requiring high impact resistance.

Weight

Both materials are lightweight, though acrylic is typically lighter than polycarbonate.

Scratch resistance

Acrylic is more prone to scratching than polycarbonate. It's essential to consider the resistance to surface damage when choosing between the two materials.

UV stability

Both materials provide UV resistance, though polycarbonate generally offers enhanced protection against harmful UV rays.

Ease of fabrication:

Acrylic sheets can be easily shaped and drilled, while polycarbonate sheets require specific techniques and tools for fabrication.

Cost:

Acrylic is generally more cost-effective than polycarbonate, making it a preferred choice for projects with budget constraints.

What you should use the choice between acrylic and polycarbonate depends on your project requirements. Consider factors such as strength, clarity, UV protection, fabrication techniques, and budget when deciding which material to use for your specific application.

Cut To Size

Whether you're working on a small DIY project or a commercial project, we're proud to offer cut-to-size sheets here in the heart of Melbourne.

Same Day Delivery

For orders placed before 2pm, we're proud to offer same day delivery within Melbourne Metro.

Where We Are

Frequently Asked Questions

Shipping & Returns

We offer same-day shipping for Melbourne metro areas and 1-4 business days delivery for everywhere else in Australia.

The polycarbonate sheets are carefully packaged to ensure they arrive in perfect condition. Sheets are protected with wrapping or other cushioning materials to minimise any damage during transit.

The polycarbonate sheets are carefully packaged to ensure they arrive in perfect condition. Sheets are protected with wrapping or other cushioning materials to minimise any damage during transit.

General

Polycarbonate is extremely strong and nearly unbreakable, making it suitable for applications like police shields, awnings, sunroom roofing, and greenhouses. These panels are resistant to various weather conditions and maintain their appearance for many years.

Polycarbonate sheets can be easily cut using a circular saw or a jigsaw. Circular saws are best for cutting larger lengths, while jigsaws require careful handling to ensure proper cuts.

Although polycarbonate sheets may change colour over time due to sun exposure, Excelite's UV-coated polycarbonate sheets maintain their colour longer.

Polycarbonate sheets require minimal maintenance. Gentle cleaning with warm soapy water and a soft cloth is typically sufficient. Avoid abrasive cleaners, brushes, or pressure washing, as these may damage the UV-resistant coating or scratch the sheets

Roofing

The best sheeting for a roof depends on the specific requirements, with multi-wall, solid, and corrugated polycarbonate sheets each offering unique benefits.

Although polycarbonate sheets are tough and durable, they should not be walked on. They can withstand many impacts, but might dent or scratch under the weight of a person. Additionally, their surfaces are slippery due to the UV-resistant film, posing a risk of slipping and injury.

Corrugated and twin wall polycarbonate sheets are typically the least expensive varieties. Despite the lower price, these sheets can endure Australia's harsh weather conditions, but selecting the wrong type may lead to more expenses in the long term.

Pergolas & Greenhouses

Excelite's popular glass-look polycarbonate flat roofing is an excellent choice for a pergola roof. It is easy to install, low-maintenance, and watertight, making it a great alternative to glass.

or a pergola enclosure with a glass-like appearance, use a 4-6mm thick solid polycarbonate sheet. Alternatively, use twin-wall polycarbonate panels for a more affordable, yet less transparent option.

Twin wall polycarbonate is ideal for greenhouse construction due to its insulating properties and minimal framing requirements. Excelite Softlite polycarbonate sheets are another excellent option for greenhouse materials, especially for tunnel greenhouses.

Subscribe to our newsletter

Promotions, new products and sales. Directly to your inbox.